Understanding 4140 Seamless Tubing: Key Insights for Construction and Decoration

4140 seamless tubing is a type of alloy steel tubing that is widely recognized for its strength, ductility, and versatility in various applications, particularly in the construction and decorative materials sectors. The designation "4140" refers to a specific alloy that contains chromium, molybdenum, and carbon, which contributes to its exceptional mechanical properties. It is often used in applic

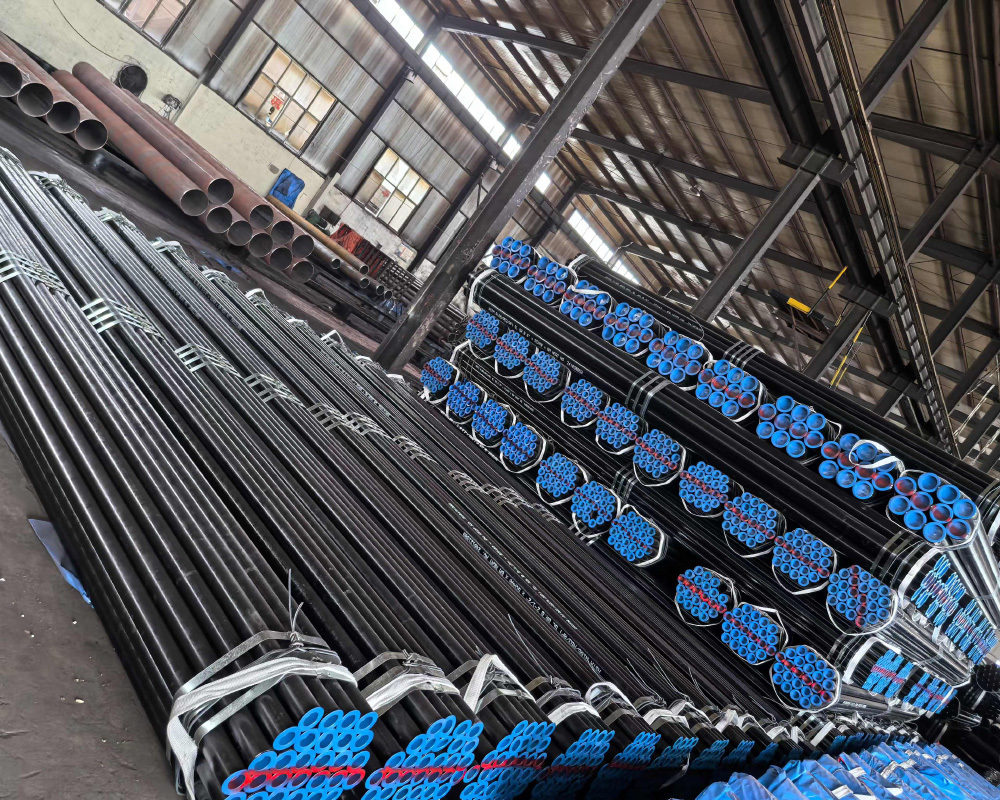

4140 seamless tubing is a type of alloy steel tubing that is widely recognized for its strength, ductility, and versatility in various applications, particularly in the construction and decorative materials sectors. The designation "4140" refers to a specific alloy that contains chromium, molybdenum, and carbon, which contributes to its exceptional mechanical properties. It is often used in applications where high strength and toughness are crucial.

One of the defining features of 4140 seamless tubing is its manufacturing process. Unlike welded tubing, seamless tubing is formed from a solid round steel billet that is heated and then pierced to create a hollow tube. This process results in a tube with uniform wall thickness and improved structural integrity. The absence of weld seams makes it less prone to failure under pressure and enhances its fatigue resistance, making it an ideal choice for demanding construction applications.

In the construction industry, 4140 seamless tubing is commonly used in structural frameworks, supports, and scaffolding, providing a robust foundation for various projects. Its high tensile strength allows it to bear heavy loads while maintaining its shape and integrity, which is essential for the longevity and safety of structures. Furthermore, its corrosion resistance, when properly treated or coated, makes it suitable for outdoor applications where exposure to harsh weather conditions is expected.

Another important aspect of 4140 seamless tubing is its adaptability to different finishes and coatings. This capability allows it to be used not only in structural applications but also in decorative contexts, where aesthetic appeal is important. Builders and decorators can take advantage of the tubing's ability to be painted, polished, or otherwise finished to complement design schemes, making it a versatile choice for both functional and visual elements in construction.

Additionally, the machining and fabrication characteristics of 4140 seamless tubing are noteworthy. It can be easily machined, welded, and formed, allowing for custom solutions tailored to specific project requirements. This flexibility provides designers and engineers with the ability to create unique components that meet the precise needs of their applications.

In summary, 4140 seamless tubing is a robust and versatile material that plays a vital role in the construction and decoration industries. Its seamless construction, high strength, and adaptability make it an excellent choice for a wide range of applications, from structural supports to decorative elements. Understanding the benefits and uses of this material can help builders, engineers, and designers make informed decisions, ensuring the success of their projects.

One of the defining features of 4140 seamless tubing is its manufacturing process. Unlike welded tubing, seamless tubing is formed from a solid round steel billet that is heated and then pierced to create a hollow tube. This process results in a tube with uniform wall thickness and improved structural integrity. The absence of weld seams makes it less prone to failure under pressure and enhances its fatigue resistance, making it an ideal choice for demanding construction applications.

In the construction industry, 4140 seamless tubing is commonly used in structural frameworks, supports, and scaffolding, providing a robust foundation for various projects. Its high tensile strength allows it to bear heavy loads while maintaining its shape and integrity, which is essential for the longevity and safety of structures. Furthermore, its corrosion resistance, when properly treated or coated, makes it suitable for outdoor applications where exposure to harsh weather conditions is expected.

Another important aspect of 4140 seamless tubing is its adaptability to different finishes and coatings. This capability allows it to be used not only in structural applications but also in decorative contexts, where aesthetic appeal is important. Builders and decorators can take advantage of the tubing's ability to be painted, polished, or otherwise finished to complement design schemes, making it a versatile choice for both functional and visual elements in construction.

Additionally, the machining and fabrication characteristics of 4140 seamless tubing are noteworthy. It can be easily machined, welded, and formed, allowing for custom solutions tailored to specific project requirements. This flexibility provides designers and engineers with the ability to create unique components that meet the precise needs of their applications.

In summary, 4140 seamless tubing is a robust and versatile material that plays a vital role in the construction and decoration industries. Its seamless construction, high strength, and adaptability make it an excellent choice for a wide range of applications, from structural supports to decorative elements. Understanding the benefits and uses of this material can help builders, engineers, and designers make informed decisions, ensuring the success of their projects.

TAG:

Related Posts

The Essential Guide to Seamless Steel Tubes in Construction: Applications and Benefits

Seamless steel tubes are a vital component in the construction and decorative materials industry, particularly for building applications. Unlike welded tubes, seamless steel tubes are manufactured from a solid round steel billet, which is heated and then stretched or reduced to form a tube without the need for welds. This manufacturing process imparts several characteristics that enhance their uti