The Benefits of A53 Seamless Pipe in Building Applications

The Benefits of A53 Seamless Pipe in Building Applications

Table of Contents

1. Introduction to A53 Seamless Pipe

2. What Is A53 Seamless Pipe?

3. Key Advantages of A53 Seamless Pipe

3.1 Strength and Durability

3.2 Corrosion Resistance

3.3 Versatility in Applications

3.4 Cost-Effectiveness

3.5 Ease of Installation

The Benefits of A53 Seamless Pipe in Building Applications

Table of Contents

- 1. Introduction to A53 Seamless Pipe

- 2. What Is A53 Seamless Pipe?

- 3. Key Advantages of A53 Seamless Pipe

- 3.1 Strength and Durability

- 3.2 Corrosion Resistance

- 3.3 Versatility in Applications

- 3.4 Cost-Effectiveness

- 3.5 Ease of Installation

- 4. Applications of A53 Seamless Pipe in Construction

- 5. A53 Seamless Pipe vs. Other Types of Pipes

- 6. Safety Considerations

- 7. Maintenance of A53 Seamless Pipe

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to A53 Seamless Pipe

In the realm of construction materials, the choice of piping can significantly influence the overall performance and longevity of buildings. Among various options, the **A53 seamless pipe** stands out due to its unique properties and versatility. Understanding its benefits is crucial for engineers, builders, and architects who aim to create structures that are not only functional but also resilient.

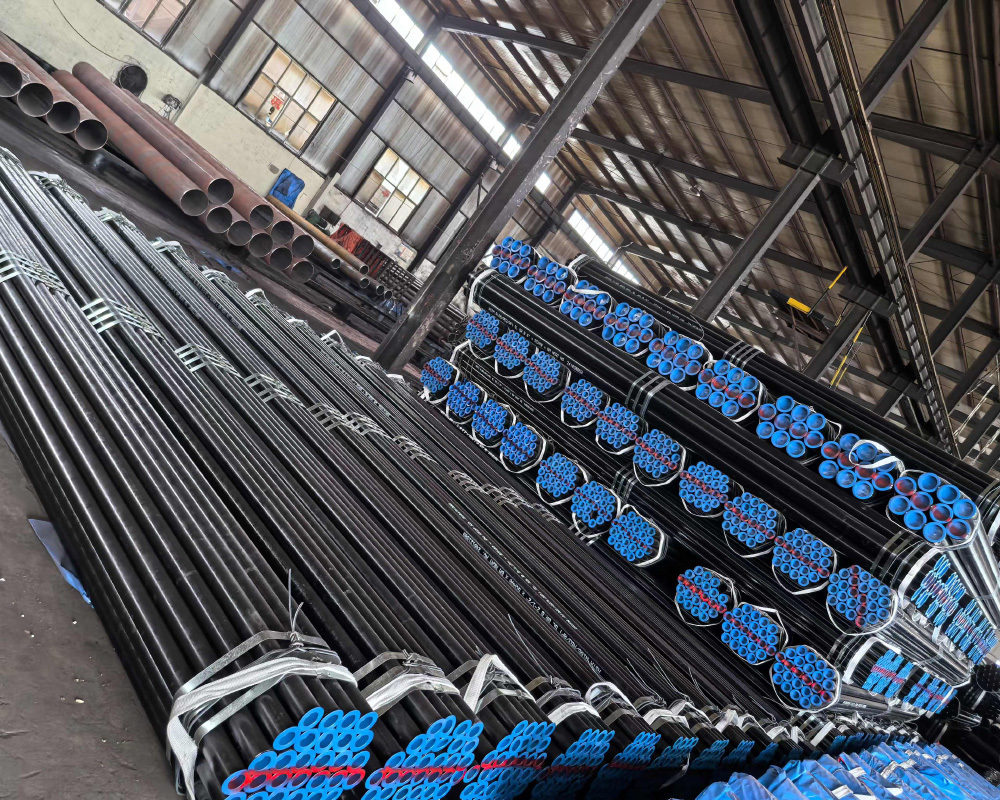

2. What Is A53 Seamless Pipe?

A53 seamless pipe is a type of carbon steel pipe that conforms to the specifications set by the American Society for Testing and Materials (ASTM). This pipe is manufactured using a seamless process, meaning it does not have any welded seams, which enhances its structural integrity. This pipe is widely used in various building applications, particularly in structural and mechanical systems.

3. Key Advantages of A53 Seamless Pipe

Understanding the advantages of A53 seamless pipe is essential for making informed decisions in construction projects.

3.1 Strength and Durability

One of the primary benefits of A53 seamless pipe is its unmatched **strength and durability**. The absence of welds means there are no weak points in the structure, making it more resistant to external pressures and impacts. This characteristic is especially important in construction, where pipes may be subjected to heavy loads and extreme conditions.

3.2 Corrosion Resistance

Corrosion can significantly compromise the integrity of piping materials over time. However, A53 seamless pipe can be manufactured with various coatings or treatments to enhance its **corrosion resistance**. This feature is particularly beneficial in areas exposed to moisture or corrosive substances, ensuring a longer lifespan and reduced maintenance costs.

3.3 Versatility in Applications

A53 seamless pipe is incredibly versatile and suitable for a wide range of applications. Whether it is in structural support systems or mechanical installations, its adaptability makes it a preferred choice among builders. Its ability to perform under various environmental conditions adds to its appeal, making it a reliable option for diverse projects.

3.4 Cost-Effectiveness

While initial costs can vary, the **cost-effectiveness** of A53 seamless pipe becomes apparent over time. Its durability reduces the need for frequent replacements or repairs, leading to overall savings in project budgets. Additionally, its ease of installation helps to keep labor costs down, making it an economically sound choice for builders.

3.5 Ease of Installation

The installation of A53 seamless pipes is straightforward due to their uniform properties. The lack of welds allows for quicker assembly and reduces the potential for errors during installation. This efficiency not only speeds up the construction process but also minimizes delays, ensuring that projects can proceed on schedule.

4. Applications of A53 Seamless Pipe in Construction

A53 seamless pipes are utilized in various aspects of building applications. Below are some of the primary areas where these pipes are most commonly employed.

4.1 Structural Applications

In structural applications, A53 seamless pipes provide essential support and strength. These pipes are often used in frameworks, columns, and beams where reliability is paramount. Their robust construction ensures that buildings can withstand environmental stresses such as wind and seismic activity.

4.2 Mechanical Applications

A53 seamless pipes are also widely used in mechanical applications, including pressure vessels and heat exchangers. Their ability to handle high pressure and temperature makes them ideal for such uses. Engineers favor these pipes for systems that require dependable performance under varying conditions.

4.3 Plumbing and Piping

In plumbing and piping systems, A53 seamless pipes are used for transporting fluids and gases. Their smooth interior surfaces minimize friction, allowing for efficient flow rates. Additionally, their strength ensures that plumbing systems remain intact under pressure, preventing leaks and failures.

5. A53 Seamless Pipe vs. Other Types of Pipes

When selecting piping for construction, it's essential to compare A53 seamless pipe with other types of pipes, such as welded or galvanized pipes. A53 seamless pipes typically offer superior strength and a lower risk of failure due to their continuous construction. In contrast, welded pipes may have potential weak points at the seams, leading to concerns over durability and safety.

6. Safety Considerations

Safety is a crucial consideration in any construction project. A53 seamless pipes, with their robust design, are considered a safer option compared to other types of pipes. The absence of welds means fewer potential failure points, making these pipes a preferred choice in high-stakes environments.

7. Maintenance of A53 Seamless Pipe

To ensure the longevity of A53 seamless pipes, regular maintenance is advisable. Periodic inspections can help identify any signs of corrosion or other wear and tear. Proper maintenance practices can extend the lifespan of these pipes, ensuring that they continue to perform effectively throughout their service life.

8. Frequently Asked Questions

1. What is the main difference between A53 seamless and welded pipes?

The primary difference lies in their construction. A53 seamless pipes are made from a single piece of material, whereas welded pipes are formed by joining pieces together, potentially creating weak points.

2. Can A53 seamless pipes be used for high-pressure applications?

Yes, A53 seamless pipes are well-suited for high-pressure applications due to their robust construction and lack of seams.

3. How do I choose the right size of A53 seamless pipe for my project?

Choosing the right size depends on various factors, including the intended use, fluid type, and pressure requirements. Consulting with an engineer can help determine the best size for your specific application.

4. Are A53 seamless pipes resistant to corrosion?

A53 seamless pipes can be treated with various coatings to enhance their corrosion resistance, making them suitable for use in challenging environments.

5. What maintenance is required for A53 seamless pipes?

Regular inspections and cleaning are recommended to prevent corrosion and ensure the pipes are functioning correctly. Addressing any signs of wear or damage promptly can help extend their lifespan.

9. Conclusion

In summary, the **A53 seamless pipe** presents numerous advantages that make it an excellent choice for various building applications. Its strength, durability, versatility, and cost-effectiveness position it as a staple in construction. By leveraging the unique properties of A53 seamless pipes, builders and engineers can ensure that their projects meet the highest standards of safety and performance. As the construction industry continues to evolve, the benefits of A53 seamless pipes will undoubtedly remain a key consideration for future developments.

TAG:

Related Posts

The Essential Guide to Seamless Steel Tubes in Construction: Applications and Benefits

Seamless steel tubes are a vital component in the construction and decorative materials industry, particularly for building applications. Unlike welded tubes, seamless steel tubes are manufactured from a solid round steel billet, which is heated and then stretched or reduced to form a tube without the need for welds. This manufacturing process imparts several characteristics that enhance their uti